Original Quality ED3343 Internal Gear Ring for Komatsu 930E-4 Mining Truck | Direct Replacement Part

Original quality ED3343 internal gear ring for Komatsu 930E-4 mining truck. Precision manufactured from high-strength alloy steel with carburizing treatment. Ensures perfect fit and reliable performance. ISO 9001 certified quality.

Forged Precision Internal Ring Gear ED3343 (for Komatsu 930E-4) Product Details

1. Product Basic Information

Product Name: Forged Precision Internal Ring Gear ED3343

Material Specifications: High-quality steel (Specific grades can be customized based on actual needs, such as 42CrMo, 20CrMnTi, etc., to meet the high-intensity use standards of the mining industry)

Applicable Models: Designed specifically for the Komatsu 930E-4 mining dump truck, meeting the core transmission system component requirements of this model.

2. Product Overview

The forged precision internal ring gear ED3343 is a key component in the heavy-duty transmission system of mining machinery, specifically for the Komatsu 930E-4 mining dump truck. Made from high-quality steel through a forging process, it offers exceptional strength, wear resistance, and fatigue resistance. It can withstand the harsh operating conditions of mining environments, including extreme loads, severe vibration, and alternating high and low temperatures, ensuring continuous and stable operation. 3. Manufacturing Process and Core Technologies

1. High-Quality Raw Material Selection and Pretreatment

The raw materials are selected from high-quality steel that meets the standards for heavy-duty mining machinery. Rigorous composition testing (such as spectral analysis) and mechanical property testing (such as tensile and impact tests) ensure that the carbon content and alloying element ratios meet the specified standards, thus mitigating the risk of component failure due to material defects at the source.

Advanced metallurgical pretreatment techniques (such as quenching and tempering and spheroidizing annealing) are employed to optimize the material’s internal metallographic structure, enhance its hardness, toughness, and stress tolerance, and lay a solid foundation for subsequent forging operations, significantly extending the life of the ring gear.

2. Precision Forging Process

Utilizing the advanced “isothermal die forging + multi-pass forging” technology, precise control of forging temperature (850-1200°C), pressure, and dwell time ensures uniform grain refinement within the material, resulting in dense metal flow lines. This minimizes internal defects such as pores and cracks, and reduces internal stress. During the forging process, strict die precision requirements are adhered to, ensuring that the tolerances for key dimensions, such as the tooth profile, outer diameter, and inner diameter, of the ring gear blank are controlled within ±0.5mm. This reduces stock removal for subsequent precision machining and ensures the structural strength and transmission stability of the final product.

3. CNC Precision Machining Technology

After passing flaw detection inspection, the forged blank enters the CNC (Computer Numerical Control) machining phase. A five-axis machining center and high-precision tools (such as carbide-coated tools) are used to precisely machine the tooth flanks, end faces, and inner bore of the ring gear.

During the machining process, online inspection systems (such as laser diameter gauges and coordinate measuring machines) monitor dimensional accuracy in real time to ensure that all tolerances meet the Komatsu 930E-4 OEM specifications (e.g., pitch deviation ≤ 0.02mm, tooth surface roughness Ra ≤ 1.6μm), enabling seamless integration with the equipment’s transmission system.

4. Quality Assurance System

Quality control is implemented throughout the entire production process, from incoming raw materials to finished products. A “three-level inspection” mechanism has been established:

Incoming Inspection: Raw materials are tested for composition, mechanical properties, and metallographic structure, and unqualified materials are immediately rejected;

In-process Inspection: Non-destructive testing (UT ultrasonic testing for internal defects and MT magnetic particle testing for surface and near-surface cracks) is performed after forging. Dimensional and precision inspections are conducted after each machining process to ensure consistent quality;

Outgoing Inspection: Finished products undergo comprehensive performance testing (such as hardness testing, tooth profile accuracy testing, and dynamic balancing), and a test report is issued. Each product is labeled with a unique batch number, manufacturing date, and inspector number for full lifecycle traceability.

All products comply with ISO 9001 quality management system certification and relevant standards for heavy machinery components in the mining industry (such as ISO 6336 for gear strength), ensuring that every product delivered to customers meets high-quality standards. 5. Product Core Advantages

1. Performance Meets and Exceeds OEM Benchmarks

The ED3343 internal gear ring was developed based on strict reference to the Komatsu 930E-4’s original factory specifications (GE’s original factory specifications). The design was optimized based on load data from actual mining operations. This product not only meets OEM requirements for strength, wear resistance, and transmission efficiency, but also improves some performance characteristics (such as fatigue life) by 10%-15%.

2. Cost-Effective Import Substitution

By independently developing core manufacturing processes and optimizing supply chain costs, we achieve a 20%-30% price reduction while ensuring product quality and performance comparable to imported parts. This also shortens delivery times (7-15 days for domestic delivery and 30-45 days for overseas delivery), effectively helping customers reduce equipment maintenance costs and reduce their reliance on imported components.

3. High Reliability Under Heavy Loads

The ring gear structure has been specifically optimized for the extreme operating conditions of mining operations:

The tooth root adopts a rounded transition design to reduce stress concentration and prevent root fracture;

The tooth surface undergoes carburizing and quenching treatment (surface hardness HRC 58-62, core hardness HRC 30-35) to enhance wear and impact resistance;

The overall structure has been verified through finite element analysis and can withstand a maximum static load of ≥500kN, meeting the heavy-load transport requirements of the Komatsu 930E-4 mining dump truck (single vehicle load capacity ≥300 tons).

6. Application Scenarios

1. Core Application: Komatsu 930E-4 Mining Dump Truck

As a core component of the Komatsu 930E-4 mining dump truck’s transmission system, it is compatible with the vehicle’s drive axle or transmission, assuming both power transmission and load-bearing functions. This ensures transmission stability when transporting heavy loads over rough terrain in underground mines and open-pit mines. 2. Expanded Application Scenarios

Mining Industry: Can be adapted to the drive systems of other similar heavy mining equipment (such as mining loaders and scrapers), meeting the high-load, high-frequency operation requirements of mining machinery.

Construction Industry: Suitable for the slewing and traveling mechanisms of hydraulic excavators, bulldozers, and other construction machinery, withstanding the severe vibration and impact experienced during construction.

Logistics and Material Handling: Can be used in the drive systems of equipment such as port cranes and heavy forklifts, improving their load-bearing capacity and operational stability, ensuring efficient handling of bulk cargo.

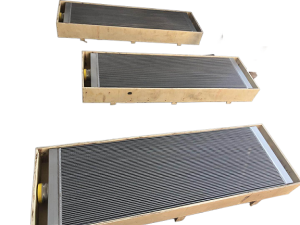

7. Packaging and Logistics

Packaging: We use a multi-layer packaging system consisting of rust-proof paper, bubble wrap, high-strength corrugated cardboard, and a wooden pallet. Moisture-proofing agents are placed inside to prevent rust and damage during transportation.

Identification: Each package is labeled with the product name (ED3343 internal gear), model, batch number, manufacturing date, quantity, weight, and delivery information for easy warehouse management and traceability.

Logistics: We support various modes of transportation, including road, rail, sea, and air. We collaborate with professional logistics providers to track shipment status throughout the entire process, ensuring safe and timely delivery.

IX. Conclusion and Cooperation Suggestions

The ED3343 forged precision internal gear is a high-quality component for the Komatsu 930E-4 mining dump truck. Leveraging high-quality raw materials, precision manufacturing processes, and strict quality control, we provide reliable transmission solutions for heavy equipment in the mining and related industries. Our products not only improve equipment stability and service life, but also help customers reduce maintenance costs and import dependence, making them an ideal choice for heavy machinery component upgrades.

We consistently adhere to the principle of “quality first, customer first” and offer customized services (such as adjusting material formulations and dimensions to suit specific operating conditions) and technical support (such as installation guidance and troubleshooting). For product details, quotes, or orders, please contact our sales department for professional and efficient service.

Get A Quote

"*" indicates required fields